Mariko Yoshida:

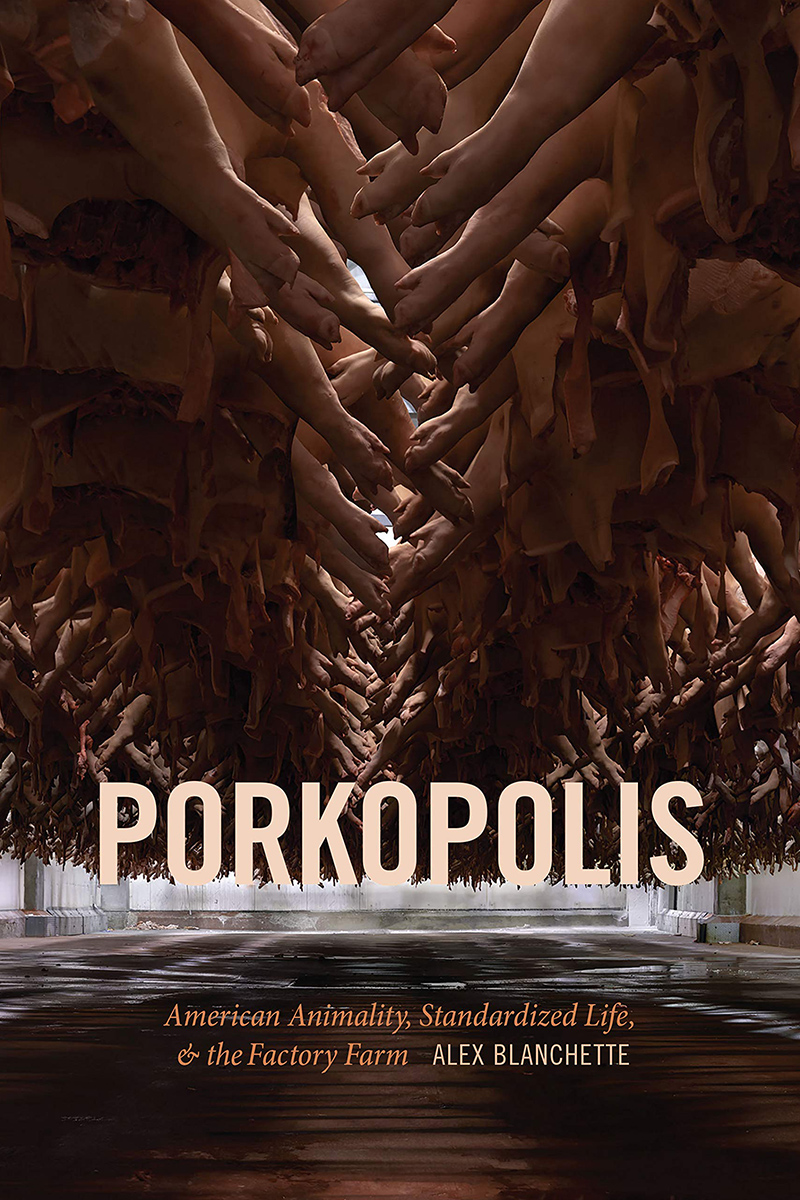

What I find thought-provoking about Porkopolis※1 is your analysis of the totality of industrial pig farming, which demonstrates how capitalist animality requires specialized human labor engineering as people are made to extract profit from every node of porcine life and death cycles. As you’ve argued, humans too are ‘tamed’ in the complete process of vertical integration, standardization, and monopolization that make uniform hogs at concentrated scale for achieving efficiency and profitability. I was fascinated by your approach in examining the changing forms of human labor alongside animals’ bodily conditions, which I think should be further discussed in the field of multispecies anthropology. Could you tell us about your thought processes that brought you to contemporary forms of capital accumulation and their linkages to more-than-human entanglements?

Alex Blanchette Porkopolis – American Animality, Standardized Life, and the Factory Farm (2020)

Alex Blanchette Porkopolis – American Animality, Standardized Life, and the Factory Farm (2020)

Alex Blanchette:

Sure. And thanks for taking the time to carefully read the book and develop these questions. I didn’t start this project with an overriding concern with issues in multispecies ethnography, or even animals. That wasn’t the starting point, especially when I was first plotting the project in 2005. I was thinking about the community where I grew up, in rural Ontario (Canada), that back then was taking on increasing inventories of animals — especially chickens, but to some extent hogs. I wanted to write a dissertation that would, in some way, contribute to the community where I grew up. At that time, in 2005, there was a lot of writing around factory farms in terms of consumptive ethics. Like, “What does it mean to eat this?” But there was relatively less on what it means to live in communities transformed by animal production, or the mundane work of industrial meat. What does it mean, I asked, to live in and work in a place that generates an absolutely huge quantity of animals; what is it like in a place that births, raises, and kills some 7,000,000 hogs in a year?

So I spent a summer driving around the United States, looking at different corporations, and found this one place whereby managers and executives seemed to be expressing a vision of the future of pork production. Expressing a legible philosophy or teleology on industrial capitalism that, for them, was really about vertically integrating the pig. That means taking historically distinct industries — such as boar studs, breeding barns, raising barns, slaughterhouses and post-processing facilities — and trying to bring it under the umbrella of one company. They claimed they were doing this in order to have greater control over animal lives — and to generate a more uniform pig. When I started going to this region in the Midwest and Great Plains, I expected to find a project of technoscientific domination over animal life. But as I lived and worked in these places, I came to see them as quite fragile projects. The reasons they were trying to create this intense uniformity across pig bodies, or conversely, trying to find more and more sites to develop labor processes and new value in the pig, was that they conceptualized themselves as running out of room to develop new profit or growth within these animals. This pig is an organism, I would argue, that has already been subjected to some 150 years of industrial processes. And so the book and the ethnography ended up being less like the typical exposé that illustrates how a corporation comes to powerfully control every single thing, an ethnography of corporate domination. It is that. But it is also about corporations’ struggles to find some sort of growth in an animal that’s already wildly over-industrialized. While individual pigs may be dominated and be subject to profound harm, living in this region taught me how the industrial pig as a model was emerging as almost a kind of agent in these sites. Everyday work and life was being organized around trying to eke out new value from capitalist hogs.

With respect to your question on labor and entanglement, I’d just add I set out to write an ethnography of the industrial pig. Porkopolis is not about pigs in general, about some kind of timeless biological beings. And I understand “industrial pig” to mean, in part, an organism that is conjoined with the capitalist exploitation of human labor. This is a species that is disproportionately encountered, known, and formed through relations of wage labor. In turn, my research and the book really became about tracking various human subject positions, forms of consciousness, and labor tasks that emerge to corral this hyper-industrialized being.

§

Yoshida:

Among various industrial animals premised on replicable modules of animality, why did you pick hogs in particular?

Blanchette:

There were a few reasons for this. I came to see pigs as the first animal species to undergo intense industrialization. At least in the United States, the industrialization of cows’ lives, for instance, remains uneven. We still have farmer-owned cow-calf operations, or cattle ranches, whereby animals live most of their life outdoors in wide expanses of land before entering feedlots and then slaughterhouses. And on the other hand, there are chickens, which some people take as the model of farm industrialization today. Chickens are a relatively recently industrialized organism, really from the 1950s. And so in one sense, I wanted to look at a species that would allow you to study not something that’s just a matter of recent industrialization, or something that just happened in the 1980s. I wanted to study an animal that has been subjected to a longer timeline of industrialization.

The second reason is organization. Typically, in the United States, chicken production is organized around contracts. So a corporation, let’s say a meat-packing corporation or a feed milling corporation, contracts with ostensibly independent farmers to raise their chickens. The pork sector is split 50-50 between these kinds of contracting arrangements, and the sorts of companies that I ended up studying, that had, in their words, “moved beyond the contracting arrangement.” They owned all of the buildings and most of the land themselves — and operated almost exclusively through wage labor with few contracted farmers to essentially do away with the farmer. When I was first developing the project, I was interested in theoretical questions that seem obvious, basic, but also might be viewed as a bit esoteric. Things like, “what is the ‘factory’ in the factory farm?,” or “what is the ‘industrial’ in the ‘industrial pig’?” When I mention that the companies that I studied seemed to almost have a legible philosophy on the nature of capitalism, one dimension of that was that some of their managers would frame their operations as passing through so-called developmental historical stages of industrialism. They could see themselves as mimicking other industries that started with contracting or the older “putting out” system of home-based labor that then eventually moved into factory production, vertical integration, and direct ownership.

Long story short, in the early 2010s, the pig was simply the most intriguing species from which to explore the very process and idea of so-called “factory” farming. And as much as it was a timely project, as we could see vertically integrated companies taking over more and more animal production across the globe, the whole thing had a curiously untimely air about it. Here we are supposed to be in a post-industrial United States, but there are these reflexive, willful industrialization projects unfolding in rural pockets of that country.

§

Yoshida:

Through the life-and-death cycles of porcine species, industrial agribusiness at massive scales reorganizes not only human communities, but human and nonhuman bodies’ engagement with the ‘domus’ that surrounds feed mills, genetics facilities, hog growing barns, slaughterhouses, pet food factories, and bone rendering operations. In Porkopolis, you mention that a manager lectured you on Japanese manufacturing theory. I’m struck by the fact that the contemporary American pork industry has been structured as a vertically integrated model based on post-World War II Japanese manufacturing systems.

Blanchette:

That was surprising to me. It can be challenging, especially in the United States, to enter into dialog with some of these companies. Many companies tend to be a bit cautious, if not outright secretive. My approach was just to be very honest, give people a very clear sense of what I was doing. And as I noted, one of my early questions was precisely “what is the factory in the factory farm?” In the United States, “factory farm” is kind of considered a negative word. It’s usually a term of derision. And I expected that very question would upset people. But I was surprised that once we talked about the project more, some executives and managers would basically say, “we’re interested in that question, too.” Obviously, in ways different from my own interests. But they were nonetheless training their employees and fellow managers in statistics, lean manufacturing, and quality improvement models.

As I took some of those manufacturing theory classes alongside managers, I found that there were a few reasons for this training. The first is that we have to understand that vertical integration of an animal species is complicated. All of the different worksites across the pig’s life and death cycle come with distinct histories, cultures, and material labor processes. The slaughterhouse has been a site of industrialization going back to the 1860s in Cincinnati. Farms have only more recently entered into more intensified processes of confinement and industrialization. Someone who grew up in a meatpacking town and then rose up through the ranks has a very different background from someone who grew up on a rural farm around animals. Similarly, the material act of artificially inseminating sows — the labor process itself — is a radically different one from slaughtering 19,000 pigs in a day along a kind of Fordist disassembly line. So what they wanted to do with these classes, first of all, is just to provide a space where people can be in the same room with each other. As I heard a CEO once put it, “we’ve integrated our pigs, now we need to integrate our people.” These classes also allowed them to develop a shared language of quantitative metrics that let them abstract from the particularities of inseminating sows, birthing pigs, or slicing hams.

Second, one of the things I didn’t anticipate is the degree to which some of these kinds of operations were set up as transnational export zones in the early 2000s. Their project was to move as much pork as they can outside of the United States, and especially to Japan and South Korea. Wholesalers there will pay more for what they consider good quality pork. Some companies are becoming increasingly dependent on finding more and more sites to take different parts of pigs — in order to try to create more value within this kind of already-overvalued organism. Some people felt that developing this knowledge and fluency in post-World War II manufacturing principles would allow them to better communicate with wholesalers across the globe, and to some extent speak the very manufacturing languages that these wholesalers abided by.

The final thing I’ll add is that these classes are called quality improvement classes. When managers say “quality,” they mean decreases in process variation. They mean less variation in the labor processes, environments, and inputs that go into pigs — and, in turn, they hope that will lead to more uniform animal muscle. Quality is uniformity: the characteristic that global wholesalers prize to build their brands.

These courses were interesting to me because they represented a site where I could watch people reflexively try to work out what it means to industrialize an organism in the early 21st century — to explicitly take epistemologies that were first developed, for example, in an automobile factory and then translate them onto the generation of a biological being. But, of course, they are only classes. As the first part of your question suggests, making pigs become more and more uniform over time is not just a matter of managerial training. It necessitates new forms of control and engineering across every phase of the pig’s life and death — from genetic design in breeding, to feed pellet composition, and to disciplining how workers act alongside this species whether it is a boar, a sow, a piglet, or a carcass.

A man inspecting the conditions of hogs at around four months of age.

A man inspecting the conditions of hogs at around four months of age.

§

The Making of Porcine Uniformity

Yoshida:

The Japanese pork industry today is heavily reliant on a global logistical infrastructure, as shown by the fact that nearly 30% of the pork imports into Japan come from the US. The domestic feed industry, too, cannot subsist without imported feed ingredients. Japanese buyers look at expanding purchases, paying for processing in the US instead of back home, and shipping value-added products to Japan in order to make higher profitability. You mention in the book that not only the type of cut, but the texture of fattiness for a particular flavor is specified by the buyers and sellers through the chain. Furthermore, interestingly, longevity and ability to retain a color and water during travel is very essential for logistical quality. How do these global logistical operations as a divided form of labor across countries contribute to making uniform pork? How is human labor formed in the process of this global logistical variation?

Blanchette:

I think the broader question that you’re posing is how these companies try to achieve a form of animal raising and killing that get more and more uniform over time. Following managers’ efforts to create standardized hog life (and, in turn, make themselves and their employees live out standardized lives) really shook up how I understood the logic of contemporary factory farms. When I went into this place, I expected it to be a matter of increasing automation and technology-driven domination over landscapes and animal lives, and that the system would be less and less dependent on human labor. One of the typical stories of industrialization that we tell is it is a matter of constantly reducing paid labor. And while all pigs in this place are kept indoors and in climate-controlled environments, with things like automated feeding machines, they still require intense amounts of human labor. Indeed, creating a more uniform hog might actually require more human labor. Or, at least, more varied forms of tasks and points of intervention across the life/death cycle.

Even in the highly industrialized slaughterhouses, which we’re now seeing in the wake of COVID-19 emerging as a hotspot for viral spread, we have 2,500 people working alongside conveyor belts. Given the still-existing variations in animal bodies and muscles, they still need thousands of people to make identical motions and adjust on-the-fly to uniformly cut apart animals given differences in tendon or fat distribution. And having the hogs all reach exactly 285 pounds at six months actually requires incredibly intensive labor — continually finding more and more spots within the pig’s life and death cycle where you can develop labor processes. In some senses, I think standardized life is a process of unpacking and remaking the pig to have human labor mediating the species at deeper and deeper facets of its existence. Or, in other words, turning the pig itself into a kind of carnal terrain for more and more labor extraction. And so that includes everything from monitoring what people do outside of work, so that diseases do not transfer across their bodies, to new kinds of labor positions such as people who only work on the pigs’ epidermis (or skin), to artificial insemination, to injecting different forms of drugs, and then through slaughter and disassembling the animal into finer and finer portions. What I found was that the industrial pig has come to require more labor than ever before.

§

Yoshida:

One of the things I find intriguing about your analysis of the industrial pig is its systematic operations that expand continuously without the discrete parts being qualitatively transformed in the commodification process. One example is the barcode informatics, as you note that there are more than a thousand product codes. You claim that the Herd as a quantitative species-making device for managers is another example that turns breeds of pig into a statistically-derived unit of life. This sort of expansion can also be seen in the contemporary Japanese pork industry that extracts capitalist value from, for instance, crossbreeding pork production commonly known as the “Sangenton” (a cross of three breeds of pork) or “Yongenton” (a cross of four breeds of pork) — which has laid the foundation for the Japanese premium pork brands. That said, do you think standardized porcine life can be further discussed in the context of “scalability” described by Anna Tsing?※2 Could you share your thoughts on industrial pork as an expansive and scalable project?

Blanchette:

Yeah. I would certainly say that achieving “scalability” is an ideal or fantasy for the architects of these operations. They would love to be able to achieve scalability — which I understand to mean that producing one pig is no different than producing 7 million pigs. But this kind of scalability seemed to be a real challenge in practice, something that was constantly failing. To move from making 6 million pigs a year to making 7 million pigs in a year, for instance, would transform both the labor process (such as increasing kill floor line speeds) and the broader ecology (such as increasing swine disease). But nonetheless, in many ways, these operations are premised on scalability — or what I refer to as totality-making. They’re at once about trying to make infinitely more pork, an organism that can become infinitely more standardized, and an animal that can be host to more products. As you noted, there are 1,100 product codes coming out of these pigs now, and these companies project a future where there will be hundreds more. One could even go further and see these sites as almost something of an experimental test zone. They’re trying to not only make more hog body parts, but to develop a modular model, one that could be easily replicated across the globe, especially in places that have much cheaper grain costs, such as South America or Eastern Europe. And while they haven’t succeeded in doing this yet, in many ways, this operation measures its profitability not only in terms of the actual pork sold, but also a kind of speculative future where they can reproduce these operations all over the place.

But in practice it was constantly faltering, and really what Porkopolis looks at, as a whole, are the ongoing and seemingly unending transformations to human beings and human communities that are necessary to maintain and gradually grow this concentration of animals. Companies were finding that in order to keep on maintaining and expanding this herd of animals in place, they actually had to focus less on the pigs themselves — and more on engineering human forms of existence that are the key inputs to industrial pork. Mundane things like human kinship, family, who lives with who, gender relations, race relations, or class relations were becoming newly questioned. Even what it means to have a physical human body was becoming noticed as a problem for this system as it either grew in scale, or got older and diseases became endemic within the local rural ecology. Without even totally noticing it while I was doing the research, much of my ethnographic work ended up focusing not on efforts to engineer pigs per se, but instead attempts to remake forms of human organization in ways that can better accommodate hog concentration.

Sows being stimulated and a boar in a remote-controlled cage (on the left side of the image), employed for his saliva pheromones.

Sows being stimulated and a boar in a remote-controlled cage (on the left side of the image), employed for his saliva pheromones.

§

Interactions between Sentient Species

Yoshida:

In How Nature Works: Rethinking Labor on a Troubled Planet※3, that you co-edited with Sarah Besky, you argue that supply chain capitalism entails farm workers’ monotonous, repetitive tasks in an identical manner, as well as collective tacit knowledge (e.g., knowledge of those who stimulate sows in artificial insemination). How does production of monotony mediated by human-hog labor regulate porcine sensorium, or porcine sentience?

Blanchette:

The article that I wrote in How Nature Works was really premised on critically interrogating how we talk about factory farming in the public sphere — often based on very limited viewpoints into these operations, such as late-night undercover exposé videos that take place when no one is there. You sometimes get the impression that there is little labor in these operations and that the pigs’ existence through machines and lack of human contact is one of just pure boredom and monotony.

Outside of the growing phase, when pigs already weigh one hundred pounds, it’s not the case that there’s little labor in these operations. In the corporations where I worked, there were 2,000 people employed in the barns for breeding and raising pigs. And what I argued in that piece is that it’s true, perhaps, that pigs live an incredibly monotonous existence — and that monotony is legible on their bodies. So many animals have bedsores from lying there, doing nothing all day locked in gestation crates. But what I want to emphasize is that actually, and perhaps paradoxically, this very monotonous existence is underpinned by intense forms of labor. I came to realize this when I was working with people in this breeding barn, this artificial insemination and piglet delivery barn called Sow #6. People often corrected me concerning how I should act around pigs, explaining how I should behave in the presence of animals. For instance, one time I went to pet a sow, kind of like I would a dog or a cat. That’s how I knew how to behave around animals, I guess. And one of my coworkers shouted at me, “Don’t touch the pigs!” She was worried that giving an unusual act of individual attention to an animal could upset her, excite her, make her bellow. And it could lead to things like miscarriages and so forth, as an animal thrives in her crate.

Other people told me that one of the things they remember most clearly from working in these operations was how the pigs were always looking at them. How pigs were always interpreting their bodies. And then in agribusiness industry journals, I just started reading all of this information and scientific research about how pigs interpret colors, about how pigs interpret sounds, and human behaviors, can have concrete effects in terms of litter sizes and pig “outputs,” and so forth. And producing pigs that come to really only monotonously do one thing — say, gestate or metabolize — requiring attention to how your body and your behavior might be emitting signs that are meaningful to animals. There was a sense that pig sentience was itself becoming something of an object of production in workers’ actions, as they always tried to act in a uniform way around uniform animals. I suppose that I take that to be a minor instance of the broader narrative that underlies Porkopolis. With increasing industrialization, we get more and more dimensions of animals — from immunity, to hormones, and then into sentient perception — becoming subjects to human work.

There’s a bigger point here. In the United States, farm work with animals is often discussed as a kind of de-skilled “manual labor” occupation. And I would certainly say that it is repetitive, and often monotonous. One of my jobs was to just sit on sows’ backs all day for artificial insemination. But I also think that we need to pay attention to the specialized worker knowledge that underpins the system. In practice, these barns and factories require deep knowledge of specific aspects of animal lives. The kinds of skill at treating, and knowledge about, piglet bodies that accrue after someone witnesses the birth of 400,000 animals is one of the main things that keeps this very fragile system afloat.

§

Yoshida:

Are those tacit knowledges of porcine sentience shared actively amongst migrant workers from one division to another? Do managers pass them down to entry-level workers?

Blanchette:

Yeah, I was trained on the job by someone who migrated to the American Great Plains from Guatemala City. He had worked in these barns for many years, and then eventually became a lower-level manager. He knew a lot. But coworkers were also sources of knowledge. There’s a lot of turnover in barns and slaughterhouses. Many people might initially appear to have only been working for a year in a given barn or kill floor. But I was surprised by how most people I was working with in those barns had worked for other pork companies over the past ten years. I had a friend who had worked in industrial animal barns across the entire Midwest. He had been employed by many different companies, and had picked up all of sorts of different tricks and ways of doing things along the way.

Conversely, the senior-most managers don’t really interact with flesh and blood pigs. They work at the level of probability, statistics, modeling to try to figure out how to increase output at the level of 180,000 breeding sows, or 7 million hogs as a whole. I do not want to generalize too much. But, by and large, it did feel to me like the knowledge of how you actually execute the process was honed and translated across generations of workers.

§

Industrial Animality

Yoshida:

I see. The US great recession, with other socioeconomic downfalls in the mid-2000s, must have affected the dynamics of the workers in the course of your fieldwork in Dixon. Another interesting thing, besides these divided operations, is that managers don’t even see workers’ faces in the biosecurity zone as it has to be highly restricted. I think there is a contrastive gap between the knowledge they have about porcine lifeworlds and things they know about their workers’ mundane social lives.

Blanchette:

There’s not simply or only a standard industrial class division in these operations between managers and workers. They also have fundamentally different experiences of animals and animality. In a vertically integrated system, people who are called “workers” tend to labor exclusively on one aspect of an animal’s existence. Partially for biosecurity concerns — out of fear that swine diseases could transfer from one site to another — people do not move across different phases of the operation with much frequency. In the book, I discuss a woman that I worked with who has quite radical expertise with baby piglets — but has never been inside the slaughterhouse. And she probably rarely encounters pigs that are older than 21 days. Other people had deep tactile knowledge with how to manifest sow reproductive instincts, but might have never cut a ham in the slaughterhouse or been in a boar stud where semen is extracted. There is interspecies intimacy there, but it’s a very capitalist kind of intimacy premised on the development of a highly precise division of labor.

Conversely, managers try to work on the entire life and death cycle of pigs. They try to work across the species in its entirety from semen all the way to 1,100 products. Their object of production is not what I imagine when I think about as a pig, like an individual animal sitting in a barn. They didn’t work on animals. They worked on animality: all of the things, from feed inputs to regional weather patterns that can be seen to make up and affect pigs in the flesh. They are also trying to develop epistemologies — including the manufacturing theories we discussed earlier — that would help them see the very disparate acts as breeding, birthing, raising, and killing animals as a single process. I guess you could say that they are not working on individual animals, but instead on the vertically integrated pig as a model.

§

Yoshida:

That sort of intimacy in the Capitalocene, the age that situates capitalism as reproduction in the web of life, is very important to think about. With that capitalist intimacy, they see the entire cycle as an assembly line. Now I understand why you indicated in one of your recent interviews※4 that “the contemporary sites of pork production…are neither anthropocentric, nor porkocentric, but rather capitalocentric.”

Blanchette:

Right. I do not love the term “anthropocentric.” It seems to imply the domination of an ecology or a species in the name of some kind of unified humanity. I prefer to see factory farms as matters of simultaneous inter- and intra-species exploitation: they are about shaping hogs into beings that contain more ground or terrain for exploitation of human workers. Conversely, and though the area where I lived and worked was something of a company town organized around both maximizing animal proliferation and accelerating the rate at which animals are killed, it would be a stretch to call these sites “pig-centric”! This is about generating productivity growth within capitalist animality — of creating new models, metric benchmarks, and kinds of animals that are never-endingly more profitable.

§

Yoshida:

While vertical integration as a form of interlocking stock ownership, controlled worksites, and a coordinated auction system is adopted by Toyosu Fish Market in Tokyo, the consequence of division of labor across its vertically-integrated network seems to differ so much from the pork industry. Usually, the intermediate wholesalers’ structure is based on family-owned business in a particular trade guild, and employees are assigned to work on particular types of fish and related specialties. Workers of wholesalers, too, are mostly trained to specialize in a particular fish species. Perhaps we can view this difference as a difference of whether or not workers have a control over a particular economic niche.

Blanchette:

Well, along those lines, one thing I’ll say is that there’s also cow production in the broader region. And many people I worked with in the hog barns would have rather been working on ranches or in beef cattle feedlots — which also, not coincidentally, pay more. But for a variety of reasons — most of them probably racist — the only form of employment primarily open to, say, people born in Guatemala or Mexico was working in the hog barns. Even if they might have previously worked on a ranch in Northern Mexico or something like that. Cows were a kind of cherished organism that has a deep history and is deemed valuable labor, culturally and economically. In this area, there was a kind of racial-class hierarchy of value across species, between pigs and cows. I am not convinced that one species or another actually requires more skill, expertise, or knowledge — but that was, in any case, the way this interspecies racial division of labor was usually justified.

Thousands of hogs rest after transport at the packing house.

Thousands of hogs rest after transport at the packing house.

§

Re-imagining Deindustrialization

Yoshida:

Regarding the post-anthropocentric biosecurity protocols, you argue in the book that “The indoor confinement of farm animals is itself often justified in the face of the viral threat of unpredictable contact with beings such as wild geese, whose risky biologies make for key natural reservoirs of zoonotic disease. Instead, this rural space, which is given over to making industrialized organisms, suggests how the laboring body and its unpredictable rhythms are engulfed by porcine illness in such a way that human sociality is now marked as one of the central virtual ‘reservoirs’ sheltering porcine disease” (Blanchette 2020: 50). On a similar note, I was thinking about zoonotic diseases, including coronaviruses. Let’s say, climate crises are rooted in the same mode of production in late neo-liberal capitalist society in which overexploitation of nature is associated with increasing contact and close proximity between humans and zoonotic disease reservoirs, and both understood as a consequence of exposing ourselves to new risks that rebound on society at large. With that in mind, I’m intrigued by the way your book ended with an urge for deindustrialization. How would the idea of deindustrialization help us reframe human-nonhuman biosociality?

Blanchette:

I love this reading. Let me just back up to say that one of the core premises of the book is that the United States, or other societies, are much less deindustrialized than we imagine. While it’s true that fewer and fewer people in the United States work in industrial jobs today, certain regions within the U.S. are hyper-industrialized. When 5,000 people help generate 7,000,000 animals in a year, their labor has been rendered radically productive, in an almost unprecedented way. Alternatively, almost every object that surrounds me right now emerges from an industrial operation. Climate patterns, or waterways, or airways, can be articulated as becoming more industrialized. Fewer people may be employed in manufacturing in the United States, but yet life continues to be mediated by industrial labor. Maybe, one could argue, in ways even more radical than it was in the 1920s or 1950s.

In current U.S. farming discussions, “industrialization” tends to mean heavy use of fossil fuels and machines, or a matter of large scales of production. I think of industrialization (and deindustrialization) more in terms of industrial capitalism: a period that disproportionately locates social, collective value in human labor and, as such, continually searches after new sites from which to exploit labor. For me, this is so evident with the pig — this being that contains within itself some 150 years of compounded capitalist engineering. This animal that has hundreds, if not thousands, of distinct products earmarked within its body. And an organism that has been disproportionately formed, known, and encountered through labor. So for me, by the end, the question becomes: how can we re-imagine deindustrialization as a conscious, aspirational, and ultimately positive project? Something that we collectively strive to achieve. Not something that means the ostracization of working people, but something that is a collective, radical, political goal. That we try to work less, that we try to work things less. That we do not organize our sense of societal contributions around labor productivity and efficiency. That we come to see value in leaving some things unworked or allowing some processes to be inefficient. That we come to relate to pigs — and countless other things — outside the mediation of work. That’s the conclusion of the book, the point where I arrive, but I do have to confess that it is really a promise for future research.

I’m currently developing a long-term project on the aftermath, ruins, and remains of Chicago’s Union Stock Yards. From the 1860s through to the 1940s, this site of meatpacking generated many aspects of American industrialism as we still think about it today. For instance, Henry Ford claimed to take the idea for the automobile assembly line from the meat-packing disassembly line. I’m in early phases of research across sixteen different sites in the city where people seem to be grappling with what it means to inherit — socially and ecologically — this now-closed killing system, and asking what it might mean to actually leave all of this behind. I want to learn, alongside people at these sites, what it might mean to say that, “we have arrived at a truly post-industrial or de-industrial moment.” The research project is about learning from on-the-ground practices of active deindustrialization, and developing a sense of what de-industrial collective praxis might entail.

§

Yoshida:

Your current project on the Chicago union stockyards sounds truly fascinating. Indeed, we need to pay deliberate attention to active and reflexive practices of making things halt to a standstill to consider what has emerged in the aftermath or on the verge of an overworked landscape — which I also believe would help us reimagine our relations to nature. Thank you so much for sharing your inspiring thoughts with us!